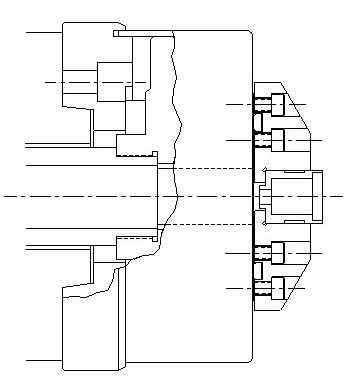

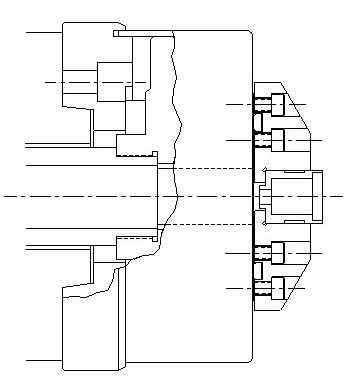

Valve body

Two inside diameters of a fuel injection valve body are to be bored while locating the workpiece OD. The valve body is machined at 3.500 r.p.m., and it is crucial that the chuck provides sufficient clamping force to machine the part, while not distorting it during chucking. One ID diameter has a 7,5 micron roundness tolerance, and distortion during chucking will prevent this tolerance from being held consistently.

Required accuracy: 0,007 mm TIR

MicroCentric replaced existing counter-weighted power chucks with HSC-Z chucks. Since the HSC-Z chuck maintains a greater percentage if its initial chucking force as machine spindle speeds increase, it was possible to lower the initial (static) chucking pressure. This eliminated the distortion previously seen on the valve body, and reduced the rejection rate of parts which did not meet the 7,5 micron roundness tolerance.

Achieved concentricity: 0,006 mm

Achieved accuracy: 0,005 mm