Specification:

| Order-No. | Accuracy µm |

Stroke ø mm |

Through |

Drawtube force max. daN* |

Clamp.-force max. daN |

Max. rpm** | Weight kg |

| KHF-165 | 0,01 | 5,5 | 46 | 2.500 | 6.300 | 6.000 | 12,4 |

| KHF-210 | 0,01 | 7,6 | 52 | 4.000 | 9.400 | 5.000 | 22,2 |

| KHF-250 | 0,02 | 8,5 | 77 | 5.000 | 12.500 | 4.200 | 34,4 |

| KHF-315 | 0,02 | 10,2 | 91 | 5.800 | 14.700 | 3.300 | 55,2 |

- * Max clamping force at max drawtube force

- ** Max. rpm with mounted standard top jaws and at max. drawtube force.

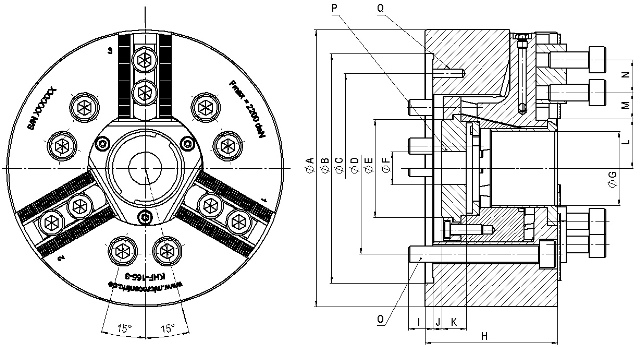

Dimensions:

| Order-No. | A | B | C | D | E | F | G | H | I | J min. | J max. |

| KHF-165 | 169,00 | 140,00 | 116,00 | 104,80 | 60,00 | 20,00 | 46,00 | 80,00 | 12,00 | 10,00 | -1,00 |

| KHF-210 | 210,00 | 170,00 | 150,00 | 133,40 | 66,00 | 30,00 | 52,00 | 91,00 | 15,00 | 10,00 | -1,50 |

| KHF-250 | 254,00 | 220,00 | 190,00 | 171,40 | 94,00 | 30,00 | 77,00 | 100,00 | 17,00 | 12,00 | -10,50 |

| KHF-315 | 304,00 | 220,00 | 190,00 | 171,40 | 108,00 | 30,00 | 91,00 | 115,00 | 18,00 | 12,00 | -14,00 |

| Order-No. | K | L max. | L min. | M max. | M min. | N | O | P max. | Q |

| KHF-165 | 19,00 | 33,50 | 30,70 | 23,00 | 10,00 | 20,00 | 6 x M10 | M55X2.0 | 3 x M6 |

| KHF-210 | 20,50 | 41,70 | 37,90 | 27,00 | 10,00 | 25,00 | 6 x M12 | M60X2.0 | 3 x M6 |

| KHF-250 | 27,00 | 54,50 | 50,30 | 31,00 | 12,00 | 30,00 | 6 x M16 | M85X2.0 | 3 x M8 |

| KHF-315 | 28,00 | 67,40 | 62,30 | 42,00 | 12,00 | 30,00 | 6 x M16 | M100X2.0 | 3 x M8 |

Features:

- Chuck sizes 165-315 mm

- Through bore 46-91 mm

- High clamping force

- Interchangeable with Kitagawa chucks of the

corresponding series - Chuck body partially wedge-hook and master jaws are hardened for high durability executed

- Maximum spindle speed 6000 r.p.m.

- With a from the adapter plate separate chuck and drawtube connector adaptabe easily to almost any rotating tool machine

Standard equipment:

- KHF-chuck

- Operating manual

For use additionally required:

- Cylinder at the machine

- Adapter plate

- Drawtube adapter

- Top jaws

©

2025

MicroCentric GmbH. All Rights Reserved.